Products

Pressure Vessels & Process Tanks

Pressure vessels are enclosed containers that hold and store liquids, vapours, and gases at a specific pressure significantly higher or lower than the ambient pressure. According to their function, they differentiated as storage tanks, boilers and process vessels. A pressure vessel may be spherical or cylindrical. Cylindrical vessels are more common, and their heads may be hemispherical, ellipsoidal, or torispherical. The axis of a pressure vessel may be vertically or horizontally oriented depending on the required standards.

As we desire to be India’s foremost process equipment manufacturers, we specialize in the design engineering, fabrication, & installation of topnotch Pressure Vessels & Process Tanks. Our team contains highly skilled professionals, including an in-house design team, quality control staff, manufacturing engineers and fabrication workforce to ensure that your tanks & other requirements meet the highest standards. LEGION undertakes design, manufacture, testing. Pressure vessels for various applications such as air receivers, columns, reactors, towers. Also, pressure vessels under Indian Boiler Regulations, 1950 such as blow down tanks, HP Heaters, Deaerators, headers for various applications.

Heat Exchangers & Condensers

For heating and cooling liquids and gasses to precise temperatures in specific process time, shell and tube heat exchangers are logical process solutions. LEGION offers a wide range of shell & tube heat exchangers, complying with various reputed design standards such as the American Society of Mechanical Engineers (ASME), Tubular Equipment Manufacturers Association (TEMA), IS, API, etc…

Heat exchangers are used in a variety of industries including petroleum, utility, paper, chemical, pharmaceuticals and metals. When it comes to shell and tube heat exchangers, LEGION wishes to earn a reputation for quality, dependability and value-added service in the market. Our Shell & Tube Heat Exchangers are designed & built in a wide variety of sizes and metallurgy as per customer’s requirements. Length can vary from 0.5 meters to 20 meters& Diameter can vary from 0.15 meters to 2.0 meters. The design and test pressure can be upto300 Kg/Cm2G. Also, the metallurgy offered includes materials like Duplex Steel, Admiralty Brass, Naval Brass, Hastelloy, Inconel, Monel, Cupro Nickel, Titanium other than the most commonly used various

Columns

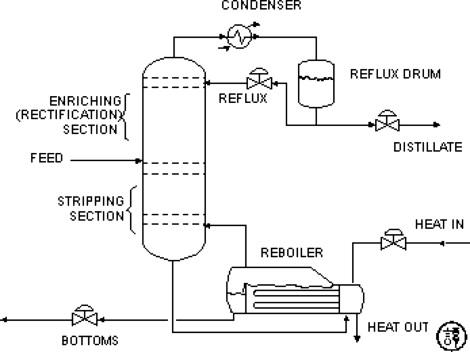

Distillation columns/towers are made either to exchange heat energy or enhance material transfer or both. A typical distillation column consists of several major parts as shown below illustration.

The management team has extensive experience in the heavy engineering industry within and outside India. We have competent QC inspectors, design associates and draftsmen experienced in the field and Of course, a Skilled Workforce to comply with any challenge. In short, you are assured of a truly genuine yet top-notch service within India. • A vertical shell where separation of the two different fluid is carried out. • Column internals such as trays, plates and packings are use to enhance component separation. • A reboiler to provide the necessary vaporization for the distillation process. • A condenser is to cool and condense the vapour leaving the top of the column. • A reflux drum to hold the condensed vapour from the top of the column so that liquid (reflux) can be recycled back to the column.

Storage Tanks

LEGION designs and manufacture storage tanks for a wide range of applications. Whether your application involves high or low temperature or pressure ratings or requires special paint or linings, we fabricate custom tanks and in a variety of steel and alloy materials complying with international manufacturing standards.

and AutoCAD for drafting.

LEGION offers design, manufacture and testing of vertical and horizontal storage tanks AS well for various applications such as hydrocarbons, potable water, fire water, effluent treatment, process chemicals storage etc. These could be designed and manufactured with respect to API 650, BS 2594 etc. With the help of competent design associates and draftsmen, custom-developed spreadsheets are used for mechanical design and AutoCAD for drafting.

Pressure Piping and Skid Assemblies

Pressure-piping is a set of pipes that are used to contain fluid at high pressure. Pressure-piping is a set of pipes that are used to contain fluid at high pressure.

LEGION offers design, detailed engineering, manufacture, testing and painting of high-pressure pipework confirming to ASME, BS, API and Client issued specifications. If piping stress analysis is required, it could be done using Ansys or Caesar by our design associates. We have a wide range of machinery such as pipe profile cutters, pipe beveling, chamfering and facing machines, band saws and power saws, SAW machines, FCAW machines, high-frequency inverter based SMAW / GTAW machines etc. We have an extensive range of WPQRs to ASME Sec IX covering a wide range of materials, thicknesses, processes and other variables.

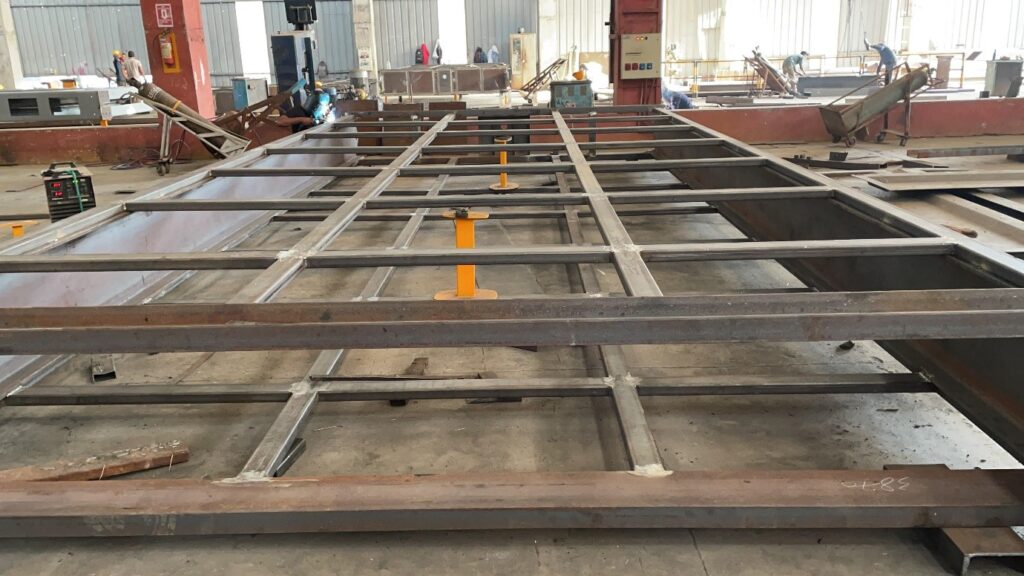

Structures

LEGION started its journey by fabrication of on-site structures and now it continues to be an early mover into new verticals and anticipating the growing demand for shop fabricated structural steel over site fabricated structural steel. The reason being shop fabricated structures are of excellent welding quality, dimensional accuracy, faster delivery in volumes and long-lasting paint finish.

LEGION offers design, manufacture, testing, painting and certification of structures for offshore and onshore applications. LEGION has a team of competent design associates, esign checkers and draftsmen who have in-depth experienced in the field.

Miscellaneous/ Customized Fabricated Equipment

LEGION offers procurement, shop fabrication, assembly, testing, painting and delivery of custom designed static process plant equipment and their components based on OEM design and engineering such as Static parts for industrial process compressors, industrial fans, Cyclones, Silos, Chimneys, Stacks, Silencers, Dampers, Ducts, Rotary Air Preheaters.

LEGION has already executed or is currently executing projects with FLEXATHERM EXPANLLOW for Fabrication of Damper INLET GUILLATIONE GATE,SIZE-7500X7500, 33 MT.